Function and Feature

- Six 30ml batching containers are placed on a tray, and the tray can be loaded and unloaded either manually or by a robotic arm.

- The equipment adopts XYZ configuration for loading the batching containers, and a turntable structure is used to switch between 5 types of powder materials for feeding.

- The types and quantities of ingredients required can be preset on the software.

- After the container is picked and positioned, feeding is carried out according to the formula, enabling automatic preparation of 6 powder materials with different compositions within 0.5 hours.

- A precision weighing unit is designed for sample weighing to ensure a batching accuracy of less than ±5mg.

- This equipment can be used independently as a standalone unit or operated in conjunction with Kejing’s dedicated scientific research robots to achieve unmanned operation.

| Technical Specification | |

|---|---|

| Power | Single-phase AC 220V ± 10%, frequency 50Hz, power 0.8KW |

| Air Source | 0.5-0.8MPa compressed air |

| Working Mode | XYZ linear module |

| Powder Channel | 5 channels |

| Powder Accuracy | The test medium is 200-mesh sand powder. The minimum single powder dosage is 20mg. The test data (with powder dosages ranging from 20mg to 13,000mg) has an accuracy of ±5mg. The weight of all the powder dosages can be traced. |

| Powder Mixing Time | 1 gram of sand powder is approximately 22 seconds, and 13 grams of sand powder is approximately 84 seconds. |

| Containers | Standard configuration: 30ml x 6. It can also be customized according to customer requirements. |

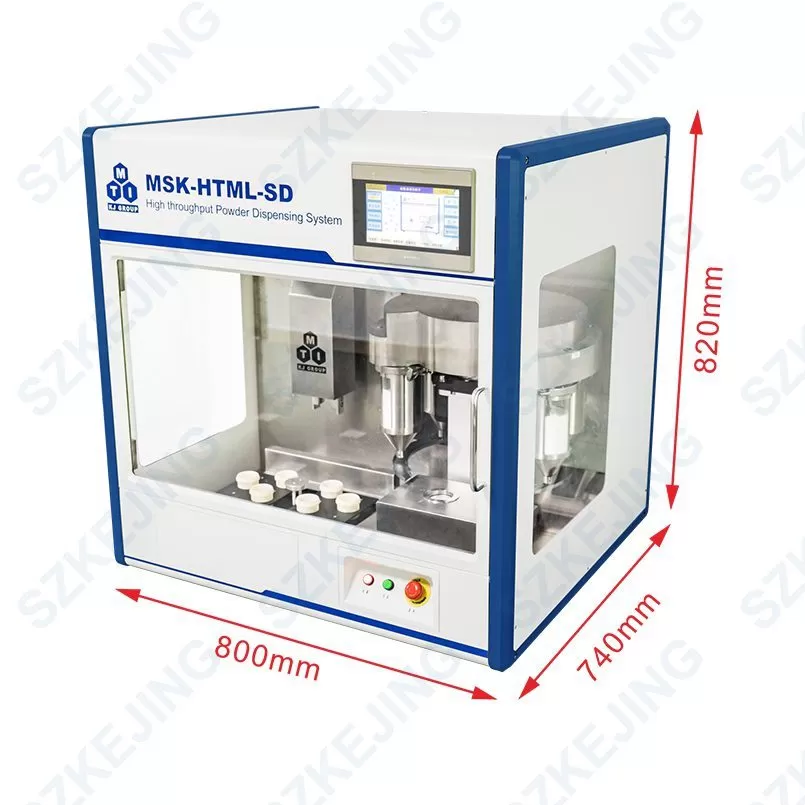

| Dimension | L800*W740*H820mm |

| Weight | About 110kg |

-02.webp)

-01.webp)